Tag: Process Improvement

Tags:

Pitfalls To Avoid During Organizational Transformation

Disruptive forces compel organizations to undertake large scale transformation initiatives to stay relevant. The speed of executing these transformations is as crucial as the initiatives itself and a lot is at stake. In such situations, it is easy to get carried away by the enormity of task at hand and lose the sight of what […]

Tanmay Vora

Not Invented Here

Organizations, teams and individuals are obsessed with doing things themselves when a similar or better solution is already available elsewhere. Thinking that if you have to get it done right then you have to do it yourself is no less than some kind of obsession. I have seen people rejecting better ideas just because they […]

Tanmay Vora

Book Announcement: Implementing Lean Six Sigma in 30 Days

I am so glad to announce that my next book is just released. It is an actionable guide titled “Implementing Lean Six Sigma in 30 Days” that aims to help readers in understanding the Lean Six Sigma methodology and solve problems that undermine quality and inhibit efficiency. This book is for business owners, quality improvement […]

Tanmay Vora

Agility in Process Improvement Initiatives

The pace of change is accelerating and business leaders who are responsible for improvements need keep up with the pace. While plan-do-check-act methodology has been around for long, the time it took was way longer. For organizational improvements (and the personal ones), what do we need today? What would business expect from improvement initiatives? A […]

Tanmay Vora

Improvement: Show Them The Results

A child develops confidence as she experiences things around her. We buy into products for which we perceive experience to be positive. We support causes that deliver positive results. In an organizational context, how can we then expect people to be totally committed to the improvement initiative at the start? People will never commit to […]

Great Story: Improvement and Tending the Garden

Improvement is not a product. It is process. On the journey to improve constantly, you can never announce that you have arrived because there isn’t a destination. If you get certified against an external standard, that is a milestone which can provide a framework to improve further. Organizations often fall in trap of thinking about […]

The Secret Sauce of Process Improvement

A colleague from a different department recently asked me, “When does this process improvement stop?”. In my response, I explained that improvement is not a destination, but a journey. It is a way for business to tune and align the operations to ongoing changes in the business. “If that is the case, how do you […]

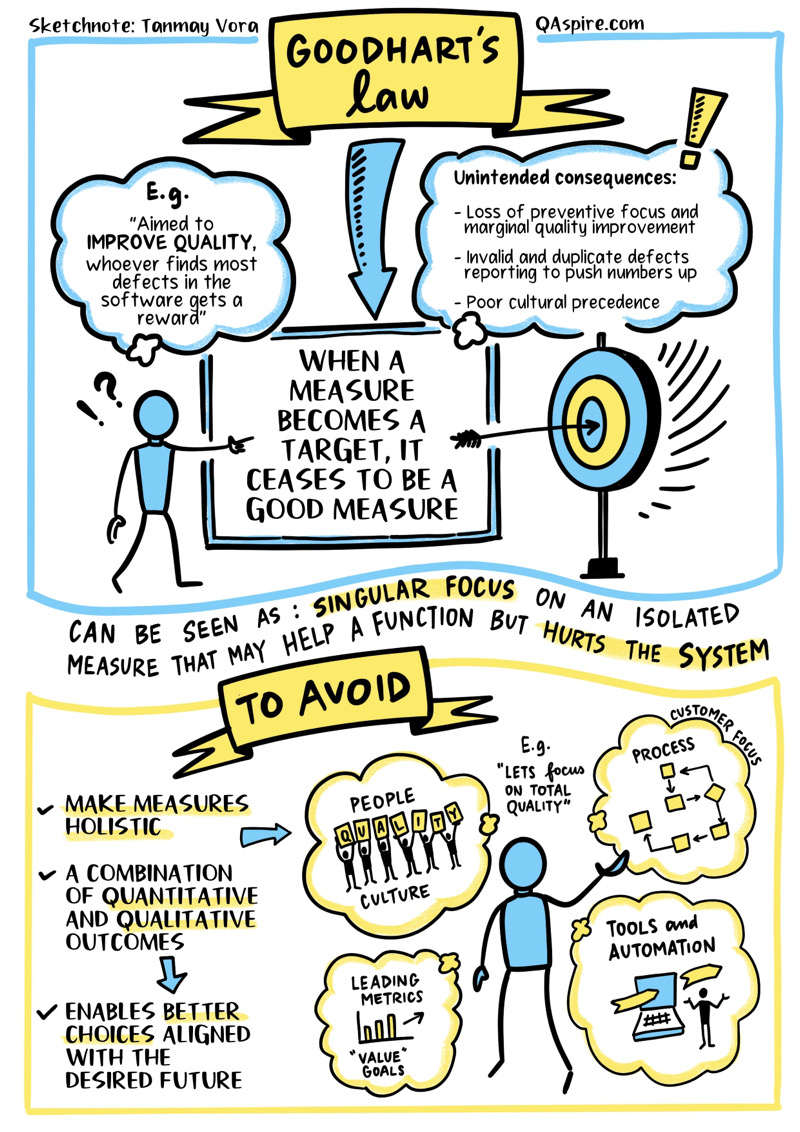

Quality: Setting Right Goals

Most improvement initiatives are heavily focused on internal goals – increasing productivity/efficiency, eliminating waste, reducing defects/costs and so on. Processes around these goals are written and implemented. People are trained, tools are implemented, energies are directed and everyone starts working hard to meet these goals. Some improvement is seen, some re-alignment is done and it […]